Vibration Condition Monitoring

Vibration Condition Monitoring

The condition of any equipment like pump-motor set, compressor-motor set, turbine-generator set, blower fan, etc. should be monitored periodically to know any defects introduced in their very early stages.

|

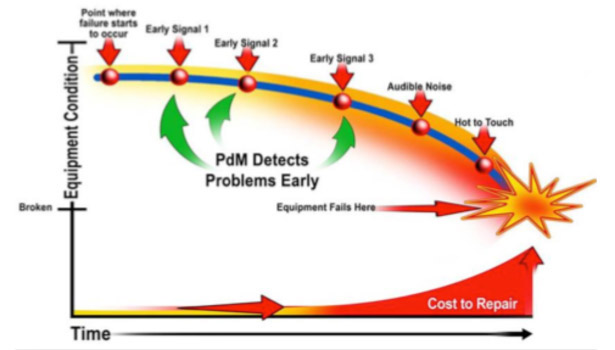

The above P-F curve (Potential Failure to Functional Failure Curve) shows a clear picture that every machine gives many signals before it goes in functional failure (breakdown failure). With the help of condition monitoring we can identify the introduction of defect in that machine at its very early stage and hence that can be taken care before it exaggerates.

|

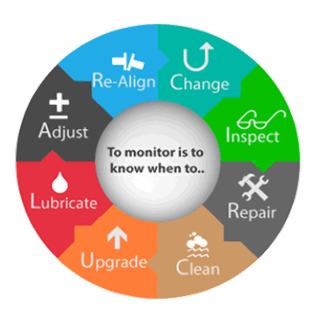

Periodic Inspection: The equipments under Condition Monitoring are inspected periodically and vibration measurements will be carried out on those. And whenever any deviation is found with previous readings, vibration analysis will be carried out on those machines.

The frequency of periodic inspection pertaining to the specific equipment will depend on severity and type of problem introduced in it. For example, for the equipment having severity of vibration very near to the vibration limit needs a frequency of condition monitoring almost monthly. For individual equipment separate inspection frequencies will be planned. The frequency of inspection will be reduced down after corrective action is taken and equipment is set right.

Our Procedure for Condition Monitoring:

The frequency of periodic inspection pertaining to the specific equipment will depend on severity and type of problem introduced in it. For example, for the equipment having severity of vibration very near to the vibration limit needs a frequency of condition monitoring almost monthly. For individual equipment separate inspection frequencies will be planned. The frequency of inspection will be reduced down after corrective action is taken and equipment is set right.

Our Procedure for Condition Monitoring:

-

Assessment of all the equipments identified by customer

-

Conducting baseline survey for identified equipments

-

Generation of baseline survey data

-

Baseline data report submission to customer with conclusions and suggestions for corrective actions

-

Identifying the equipments with higher levels of anomalies and suggest corrective actions

-

Updating baseline data of the equipments on which correction actions are taken

-

Setting frequency for condition monitoring based on the severity of vibration and prepare a timetable of condition monitoring

-

Follow the condition monitoring timetable and conduct inspections through vibration measurements and vibration analysis

-

Trend Analysis - Draw a trend of vibration measurements for every equipment

-

Reporting to customer whenever any anomalies are investigated during monitoring program

|